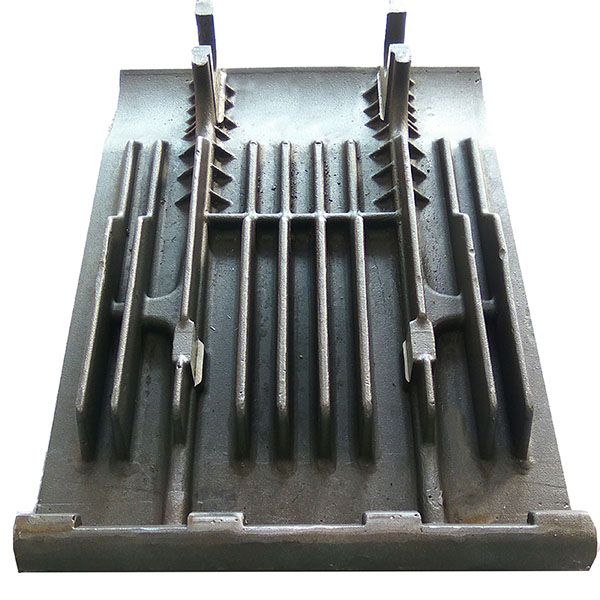

Matlakala a chesang mollo Sebōpi sa grate Setofo sa grate

Li-castings tse futhumatsang mocheso hangata li entsoe ka litšepe tse sa hloekang tse nang le palo e phahameng ea Chromium le Nickel. Li-castings tse entsoeng ka li-alloys tse sa keneleng mocheso li ntle haholo bakeng sa likarolo tse pepesitsoeng ke likhase tse ommeng maemong a batang haholo nako e telele. Liindasteri tse ruang molemo ka li-castings tse sa keneleng mocheso li kenyelletsa Matla, Liinjini, Litofo / Litofo, le Petrochemical.

Lisebelisoa tsa tšepe tse sa keneleng mocheso le tsona li bitsoa castings e kenang ka tšepe e sa keneng, e qhekellang tšepe, e futhumatsang tšepe e sa cheng.

Mocheso kenelwe tšepe ke mofuta oa tšepe motsoako e nang le matla a ho phetha molao feela le botsitso molemo lik'hemik'hale ka thempereichara e phahameng.

Lisebelisoa tsa tšepe tse sa keneleng mocheso li 'nile tsa sebelisoa ho etsa likarolo tse sa keneleng mocheso sebōping sa indasteri, mocheso o chesang mocheso, sebopi sa kalafo ea mocheso, grate e pholileng le lisebelisoa tse ling tsa liindasteri tse sa keneleng mocheso.

Tekanyetso ea ASTM A297 e koahela likarolo tsa tšepe-chromium le iron-chromium-nickel alloy bakeng sa ts'ebeletso e sa keneleng mocheso, limaraka tse koaetsoeng ke ASTM A297 ke lits'ebetso tse akaretsang mme ha ho na teko e entsoeng ho kenyelletsa lits'ebetso tse hanang mocheso tse sebelisetsoang kopo e khethehileng ea tlhahiso.

XTJ ka motlotlo fana ka mocheso kenelwe castings tšepe hore ka botlalo kopana le ASTM A297 tekanyetso, ho akarelletsa le:

• ASTM A297 Kereiti HF, Mofuta oa 19Cr-9Ni

• ASTM A297 Kereiti HH, Mofuta oa 25Cr-12Ni

• ASTM A297 Kereiti HI, Mofuta oa 28Cr-15Ni

• ASTM A297 Kereiti HK, Mofuta oa 25Cr-20Ni

• ASTM A297 Kereiti HE, Mofuta oa 29Cr-9Ni

• ASTM A297 Kereiti HU, Mofuta oa 19Cr-39Ni

• ASTM A297 Kereiti HW, Mofuta oa 12Cr-60Ni

• ASTM A297 Kereiti HX, Mofuta oa 17Cr-66Ni

• ASTM A297 Kereiti HC, Mofuta oa 28Cr

• ASTM A297 Kereiti ea HD, Mofuta oa 28Cr-5Ni

• ASTM A297 Kereiti HL, Mofuta oa 29Cr-20Ni

• ASTM A297 Kereiti HN, Mofuta oa 20Cr-25Ni

• ASTM A297 Kereiti ea HP, Mofuta oa 26Cr-35Ni

Mekhoa e fumanehang ea ho lahla bakeng sa tšepe e sa keneleng mocheso

1. Shell hlobo sebetsa ka ho nepahetseng ho betsa

2. Ho lahla matsete