Sehlopha sa rona sa Metallurgists le Baenjiniere se tla netefatsa hore o na le ts'epo e felletseng ka sehlahisoa se fanoeng.

Litsi tsa rona tsa tlhahlobo le liteko li fana ka Metallographic, Mechanical, Dimensional, tlhahlobo ea lik'hemik'hale, joalo-joalo.

Re tla hlophisa puso ea tlhahlobo le liteko ho fihlela litlhoko tsa hau. Merero ea rona ea boleng e fapana ho tloha tlhahlobisong e tloaelehileng ho ea ho netefatso e tlalehiloeng ka botlalo le ho latellana.

Re fana ka lethathamo le felletseng la liteko tse senyang le tse seng kotsi tse kenyeletsang:

1. Mochini oa ho lekanya oa Co-Ordinate CMM

2. Litšoantšo tsa mahlaseli

3. Tlhahlobo ea Magnetic Particle

4. Tlhatlhobo ea Die Penetrant

5. Tlhahlobo ea Spectrographic Chemical

6. Teko ea Tensile

7. Teko ea khatello

8. Teko ea Bend

9. Ho thatafalloa Testing

10. Metallography

Tlhahlobo ea Lik'hemik'hale

Kamora hore lihlahisoa tse tala li qhibilihe ka tšepe e qhibilihisitsoeng. Re sebelisa spectrometer ho leka lisebelisoa tsa tšepe e qhibilihisitsoeng pele re lahla ho etsa bonnete ba hore lihlahisoa li na le sehlopha sa tšepe se nepahetseng.

Tlhahlobo ea Boemo

Tekolo ea litekanyo e ipapisitse le setšoantšo ho lekanya hore na karolo ea ho lahla e kahara sebaka sa mamello, e le ho fumana phoso ea sebopeho le boholo. Ntle le moo, ho nepahala ha boemo ba machining datum, ho ajoa ha kabelo ea machining le ho kheloha ha botenya ba lebota ho lokela ho hlahlojoa ka hloko.

Tlhahlobo ea Magnetic Particle (MPI)

MPI ke ts'ebetso ea tlhahlobo e sa senyeheng (NDT) ea ho fumana litšitiso tse kaholimo le tse sa tebang tsa subsurface ho thepa ea ferromagnetic joalo ka tšepe, nickel, cobalt le tse ling tsa alloys tsa tsona. Ts'ebetso ena e kenya matla a khoheli karolong eo. Sengoathoana ka magnetized ke magnetization otlolohileng kapa e sa tobang. Matla a khoheli a tobileng a etsahala ha matla a motlakase a feta hara ntho e lekang 'me matla a khoheli a thehoa. Magnetization e sa tobang e etsahala ha ho se na matla a motlakase a fetisoang nthong ea tlhahlobo, empa matla a khoheli a sebelisoa ho tsoa mohloling o kantle. Matla a khoheli a matla a shebile moo matla a motlakase a tsamaeang teng, e ka bang a chenchana hona joale (AC) kapa mofuta o mong oa hona joale o otlolohileng (DC) (AC e lokisitsoeng).

Teko ea Ultrasonic (UT)

UT ke lelapa la mekhoa ea liteko e sa senyeheng e ipapisitseng le ho hasana ha maqhubu a mahlaseli a ntho kapa sesebelisoa se lekiloeng. Liketsong tse tloaelehileng tsa UT, maqhubu a makhutšoanyane haholo a maqhubu a maqhubu a nang le maqhubu a bohareng ho tloha ho 0.1-15 MHz, mme ka linako tse ling ho fihlela ho 50 MHz, a fetisoa ka lisebelisoa ho bona liphoso tsa kahare kapa ho khetholla lisebelisoa. Mohlala o tloaelehileng ke tekanyo ea botenya ba mahlaseli, e lekang botenya ba ntho ea teko, mohlala, ho lekola ts'enyeho ea pipework.

Thata Test

Ho thatafala ke bokhoni ba lisebelisoa ho hanela khatello ea lintho tse thata holim'a tsona. Ho latela mekhoa e fapaneng ea liteko le mefuta e fapaneng ea ho ikamahanya le maemo, likarolo tsa thatafalo li ka aroloa ka thatafalo ea Brinell, thatafalo ea Vickers, thatafalo ea Rockwell, thatafalo ea Vickers, jj. Likarolo tse fapaneng li na le mekhoa e fapaneng ea liteko, e loketseng lisebelisoa tse fapaneng kapa makhetlo litšobotsi tse fapaneng.

Teko ea Radiographic (RT)

(RT kapa X-ray kapa Gamma ray) ke mokhoa o sa senyeng (NDT) o lekolang bophahamo ba mohlala. Radiography (X-ray) e sebelisa X-ray le gamma-rays ho hlahisa radiograph ea mohlala, e bonts'a liphetoho ho botenya, bofokoli (kahare le kantle), le lintlha tsa kopano ho netefatsa boleng bo holimo ts'ebetsong ea hau.

Teko ea Thepa ea Mechini

Khampani ya rona e hlomelloa le boima ba lithane tse 200 le boima ba lithane tse 10 mochini tensile. E ka sebelisoa ho leka likarolo tsa mochini oa lihlahisoa tse ling tse ikhethang.

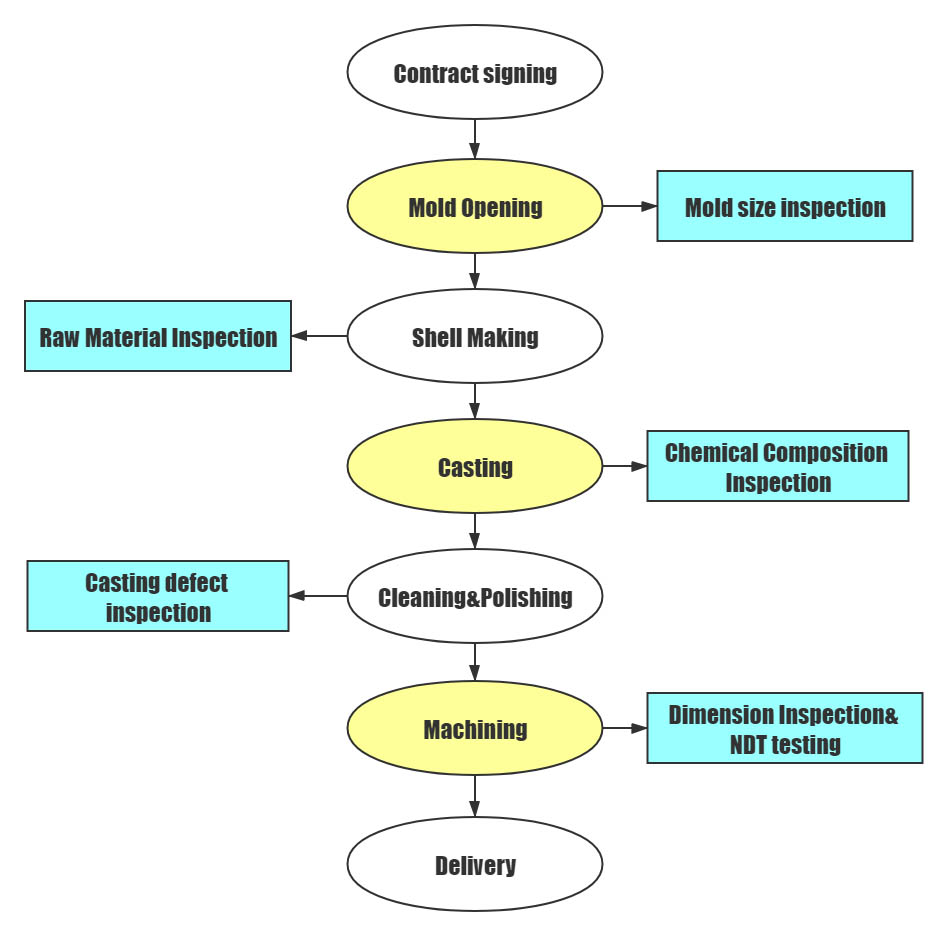

Chate ea Phallo ea Tlhatlhobo

Boleng bo phahameng, bofokoli ba zero ke sepheo seo re se phehellang kamehla. Tiiso ea bareki ke eona e re khannelang tsoelo-peleng e tsoelang pele. Kamora ho feta lilemo tse fetang leshome tsa khoebo ea machabeng, re entse ntlafatso e kholo taolong ea boleng ba li-castings. Lilemong tsa morao tjena, re ekelitse lisebelisoa tse ngata tse tsoetseng pele tsa liteko tse kang mochini oa liteko tsa 200/10 Tons Tensile, lisebelisoa tsa liteko tsa Ultrasonic, lisebelisoa tsa tlhahlobo ea likaroloana tsa X-ray, lisebelisoa tsa X-ray tsa phoso, Bahlahlobi ba lik'hemik'hale tse peli, Rockwell hardness mohlahlobi .