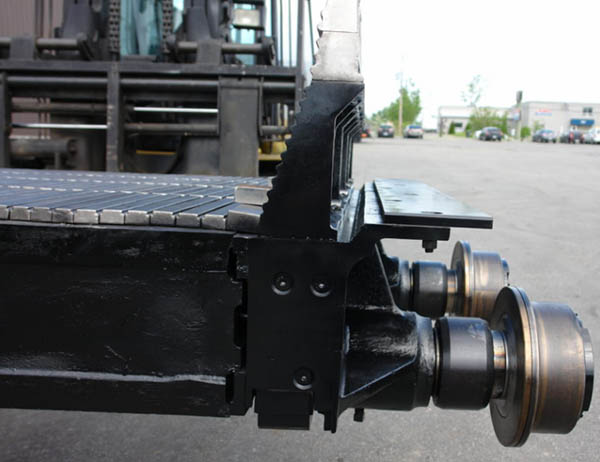

Sebaka sa Grate le lebota le lehlakoreng, Apara likarolo tsa likoloi tsa pallet le likoloi tsa sinter / pellet

1. Ts'ebetso ea ho lahla: Shell hlobo e lahla ka nepo

2. Sehlopha sa tšepe: 1.4777 1.4823 1.4837 1.4848

3.Karolo ea mamello ea li-cast: DIN EN ISO 8062-3 grade DCTG8

4.Ho mamella ha jiometri ea li-cast: DIN EN ISO 8062 - grade GCTG 5

5.Kopo: Apara Likarolo tsa likoloi tsa pallet le likoloi tsa sinter.

Ke rona mofani oa thepa ea pele ho likoloi tsa pallet le baetsi ba likoloi tsa sinter le mechini e meholo ea tšepe. Le boiphihlelo ba ho betsa bo fetang lilemo tse 10, likarolo tsena tse hanyetsanang tse hlahisoang ke rona li na le thepa e ntle ea mochini le bokaholimo bo phethahetseng. Theknoloji e holileng tsebong e laotse litšenyehelo tsa tlhahiso ea rona hantle, hore o tsebe ho odara lihlahisoa tse theko e tlase ho rona. Lilemong tsa morao tjena, keketseho ea matla a tlhahiso e boetse e netefalitse letsatsi la hau la thomello.

Tšepe Kereiti re tloaetse ho sebelisa. E ka ba joalo ka litlhoko tsa hau.

Lik'hemik'hale% ea tšepe ea GX130CrSi29 (1.4777): EN 10295-2002

|

C |

Si |

Mong |

Ke |

P |

S |

Kr |

Mo |

|

1.2 - 1.4 |

1 - 2.5 |

0.5 - 1 |

max 1 |

max 0.035 |

max 0.03 |

27 - 30 |

max 0.5 |

Lik'hemik'hale% tsa tšepe GX40CrNiSi27-4 (1.4823): EN 10295-2002

|

C |

Si |

Mong |

Ke |

P |

S |

Kr |

Mo |

|

0.3 - 0.5 |

1 - 2.5 |

max 1.5 |

3 - 6 |

max 0.04 |

max 0.03 |

25 - 28 |

max 0.5 |

K'hemik'hale% ea tšepe GX40CrNiSi25-20 (1.4848): EN 10295-2002

|

C |

Si |

Mong |

Ke |

P |

S |

Kr |

Mo |

|

0.3 - 0.5 |

1 - 2.5 |

max 2 |

19 - 22 |

max 0.04 |

max 0.03 |

24 - 27 |

max 0.5 |

K'hemik'hale% ea tšepe GX40CrNiSi25-12 (1.4837): EN 10295-2002

|

C |

Si |

Mong |

Ke |

P |

S |

Kr |

Mo |

|

0.3 - 0.5 |

1 - 2.5 |

max 2 |

11 - 14 |

max 0.04 |

max 0.03 |

24 - 27 |

max 0.5 |

| Mechini ea mechini (ASTM A297 Kereiti HH) 1.4837 | UTS: Min 75 Ksi / 515 Mpa |

| YS: Min 35 Ksi / 240 Mpa | |

| Ho kopanya: ho 2 ho: Min 10% | |

| Bothata: Min 200 BHN (libaka tse 3 tse sa tloaelehang) " | |

| Microstructure / Metallography | Boholo ba moaho oa Austenitic o nang le li-carbide tse qhalakantsoeng |

| SoundnessTest / X-ray kapa UT | RT ka ASTM E446 Level II |

| UT ka ASTM A609 Level II | |

| NDT / LPI kapa MPI | MPI ho latela ASTM E709 / E125 LEVEL II |

| LPI ho latela ASTM E165 Level II " | |

| Tlhahlobo ea ho qetela ea pono | Lekala la II la ASTM A802 |

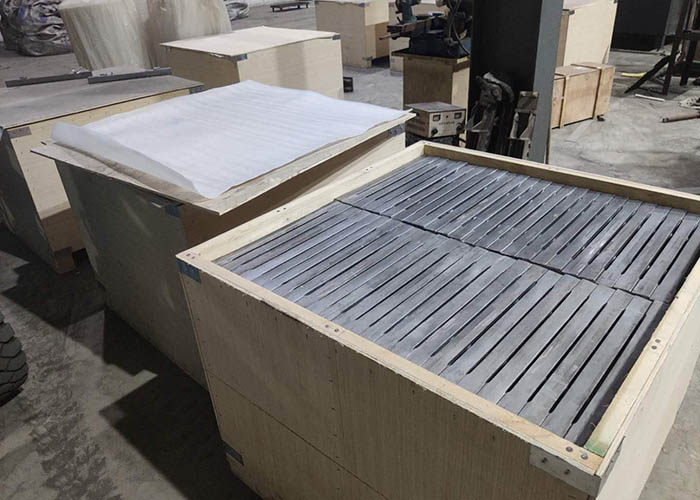

| Sephutheloana | Nyeoe ea tšepe kapa nyeoe ea lehong. |

Moruong oa hajoale oa tlholisano, ho boloka boleng ha o ntse o fokotsa litšenyehelo ho ka ba phephetso khoebong e ngoe le e ngoe.

Empa ho sebelisana le xtj, ha ua tlameha ho nahana ka eona. Re litsebi fektheri, phepelo e tobileng ka mor'a tlhahiso. Hape ho na le basebetsi ba botekgeniki le sehlopha sa kamora thekiso ho u fa litšebeletso tsa mahlale. Ka tsela ena, o ka fumana litšebeletso tse ntlehali ha o ntse o fokotsa litšenyehelo.

Bakeng sa lipotso tse ling kapa lipotso tsa mahlale, ka kopo ikopanye le Sehlopha sa Ts'ebeletso sa XTJ. Re tla fana ka tharollo e utloahalang ka ho fetisisa ea tekheniki le khotheishene e ntle ho latela sehlahisoa sa hau.