Li-grates tse tsamaeang & Chain Grate & poleiti ea ho roala ho Grate-kiln

Ha re ntse re fane ka limela tse ngata tsa pellet ka lilemo tse ngata, lits'ebetso tsa rona tsa ho lahla le ho betla li holile haholo. Lilemong tsa morao tjena, hoo e ka bang ha ho amoheloe litletlebo tsa bareki. Haeba u na le tlhokeho efe kapa efe, ka kopo ikopanye le sehlopha sa rona. Re tla u fa tharollo ea litsebi.

Lintho tseo re li sebelisang likarolong tsena hangata ke litšepe tse sa keneleng mocheso. Mocheso o hanyetsang mocheso ke thepa e nang le matla a phahameng le botsitso e sebelisoang mocheso o phahameng. E sebelisoa khafetsa liindastering le masimong a joalo ka tšepe, kalafo ea mocheso, samente, limela tsa motlakase joalo-joalo. Ho ea ka lits'ebetso tse fapaneng, mofuta ona oa thepa o hloka ho ba le botsitso bo botle, ho ts'ireletseha le botsitso ba microstructure ntle le matla a phahameng a mocheso le ho hanyetsa ts'enyeho e phahameng ea oxidation.

(1.4848): EN 10295-2002

|

C |

Si |

Mong |

Ke |

P |

S |

Kr |

Mo |

|

0.3 - 0.5 |

1 - 2.5 |

max 2 |

19 - 22 |

max 0.04 |

max 0.03 |

24 - 27 |

max 0.5 |

Lik'hemik'hale% ea tšepe ea GX130CrSi29 (1.4777): EN 10295-2002

|

C |

Si |

Mong |

Ke |

P |

S |

Kr |

Mo |

|

1.2 - 1.4 |

1 - 2.5 |

0.5 - 1 |

max 1 |

max 0.035 |

max 0.03 |

27 - 30 |

max 0.5 |

Molemo oa rona

1. Re sebelisa li-shell tsa hlobo tse nepahetseng. Lihlahisoa tse entsoeng ke rona li lula li na le boleng bo holimo ebile ha ho na liphoso tsa ho lahla.

2. Re hlahisitse likarolo tsa ho roala limela tsa pellet ka lilemo tse ngata. Re na le boiphihlelo bo monate ba ho e etsa.

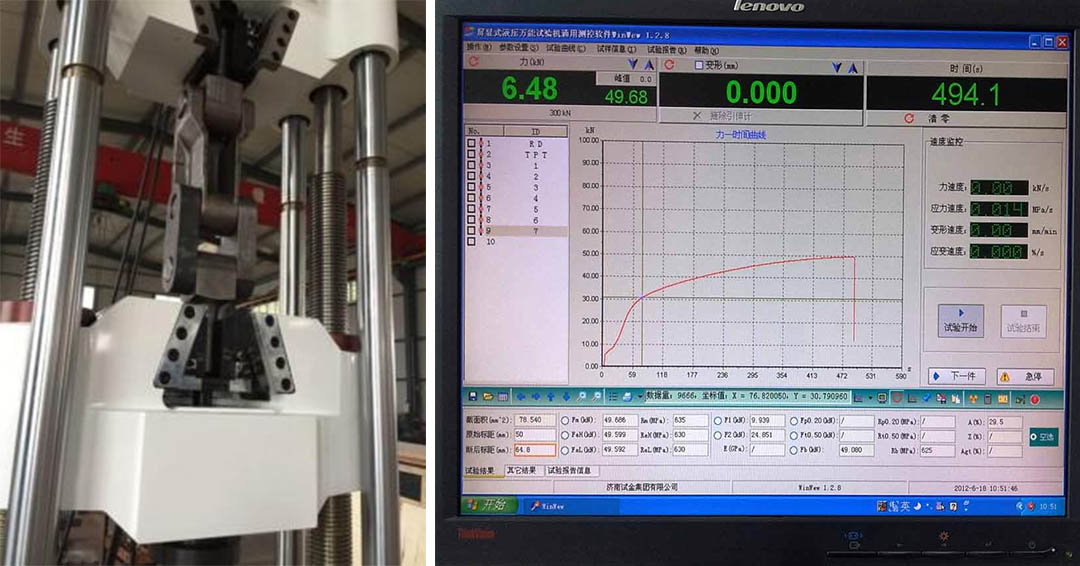

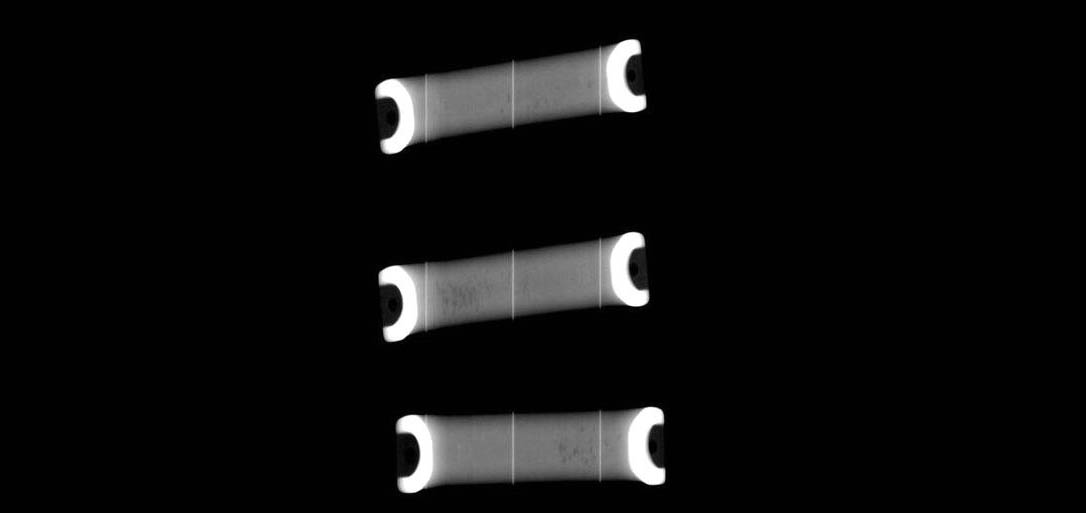

3. Re na le lisebelisoa tse felletseng tsa tlhahlobo.

Mochini oa liteko oa lithane tse 200 ho leka thepa ea mochini oa Chain Grate

Lisebelisoa tsa RT ho leka liphoso tsa kahare ho castings.

Bakeng sa lipotso tse ling kapa lipotso tsa mahlale, ka kopo ikopanye le Sehlopha sa Ts'ebeletso sa XTJ. Re tla fana ka tharollo e utloahalang ka ho fetisisa ea tekheniki le khotheishene e ntle ho latela sehlahisoa sa hau.

Apara ke lebala le rarahaneng mme ho na le mefuta ea ho roala.

Mefuta e fapaneng (le metsoako) ea mekhoa ea ho roala e hloka mekhoa e fapaneng ea khetho ea thepa le moralo.

Abrasive Wear - e etsahala ha bokaholimo bo thata bo thellisa holim'a lefatše le bonojana. Ka kakaretso, ho fokotsa moaparo o tenang o hloka thepa e thata. Likopo li kenyelletsa li-chutes le li-feed hopper tse bonang ho thella.

Apara e senyehang - e etsahala ha likaroloana li ama bokaholimo. Le ho tlosoa ha lintho butle-butle linthong tse itšehang le tse phunyeletsang, matla a kinetic a likaroloana tse amang maikutlo a ka baka ho thatafala ha mosebetsi le ho phatloha ho hoholo ho ka lebisang ho delamination le spalling. Ho nahanoa ka thatafalo ea lintho tse bonahalang hammoho le thatafalo ea thepa hammoho le moralo oa semela, mohlala, phatsa Angle Angle le Velocity li bohlokoa ho laola ho senyeha hoa litšila. Likopo li kenyelletsa pneumatic le hydro e fetisang, grizzlies, skrini le maholiotsoana.

Mofuta oa ho roala ke motsoako oa ts'enyeho le ho roala. Moaparo oa mochini o ka eketsoa haholo ke tšebetso ea lik'hemik'hale lipakeng tsa lintho tse seng li tsofetse le sekhahla se senyang tikolohong ea kopo, mohlala, Paddle Mixers ho Super Phosphate Production. Khetho ea lisebelisoa e bohlokoa haholo ho ntlafatsa litšobotsi tsa ts'enyeho tsa karolo eo.

XTJ Tlhahiso ea Lihlahisoa tsa tšepe e sa keneng molemong oa ho sebetsana le maemo a boima ho Quarrying le liindastering tsa merafo.

Sehlopha sa rona sa Metallurgists le Mechanical Engineers se tla sebetsa haufi le uena ho netefatsa hore re utloisisa litlhoko tsa hau mme re u khotsofatsa ka litlhoko tsa tlholisano ea lefatše.

Re fana ka lisebelisoa tse fapaneng tsa ho lahla thepa ea Wear le bokhoni bo felletseng ba kalafo ea mocheso ho ntlafatsa thepa ea hau ho fihlela litlhoko tsa hau.

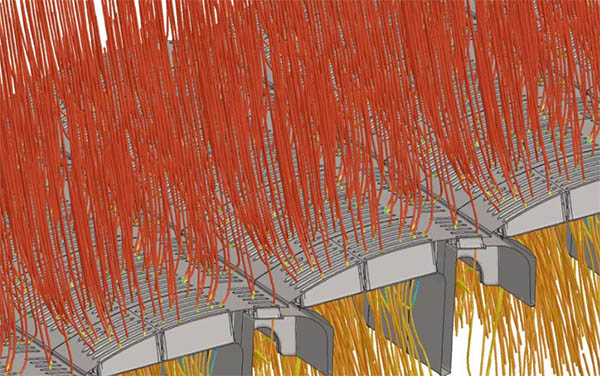

Grate e tsamaeang hantle

Li-grates tse qetileng hantle

Tlhatlhobo ea kopano ea grate ea kopano