Senya litšepe tsa grate ea tšepe, apara likarolo tsa litšila ho sebōpi sa matla

1. Ts'ebetso ea ho lahla: Shell hlobo e lahla ka nepo

2.Tsela ea tšepe: GX130CrSi29 (1.4777) (Le eona e ka ba tlhokahalo ea hau)

3.Karolo ea mamello ea li-cast: DIN EN ISO 8062-3 grade DCTG8

4.Ho mamella ha jiometri ea li-cast: DIN EN ISO 8062 - grade GCTG 5

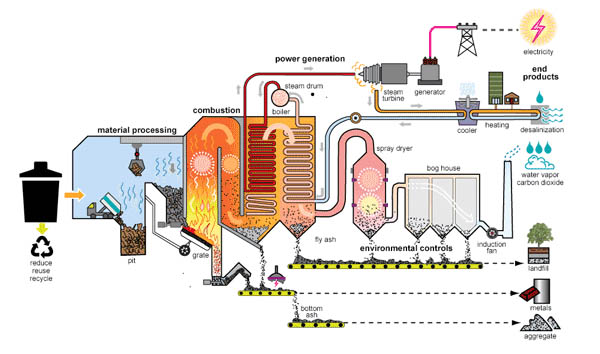

5. Kopo: Lits'ila ho lijalo tse chesang motlakase.

Ho lahloa ha litšila joale ke bothata bo tebileng lefatšeng ka bophara. Litšila ho matla ke kalafo e loketseng ka ho fetisisa hajoale. Lilemong tsa morao tjena, linaha tse ngata tse nang le matla a maholo moruong li se li qalile ho ela hloko ntlha ena. Ho tsetetsoe chelete e ngata ho aha libaka tsa motlakase oa ho chesa litšila. Sena ha se tlise ntlafatso e kholo tikolohong ea rona feela. Ka nako e ts'oanang, e re tliselitse melemo e mengata moruong.

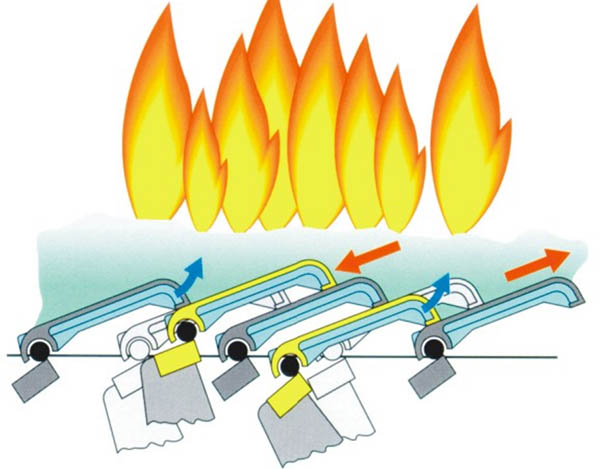

Joalokaha ho bonts'itsoe setšoantšong, li-bar bar li bapala karolo ea bohlokoa ho chesa litšila. Ka mocheso o phahameng le tikoloho e thata haholo, boleng ba boleng bo tlase bo tla ama ts'ebetso ea ts'enyo ea litšila, 'me bophelo ba eona ba ts'ebeletso bo bokhutšoanyane haholo. U hloka ho e nkela sebaka khafetsa.

Leha ho le joalo, ka lilemo tse fetang 10 re lahla boiphihlelo, re ka u rarollela mathata.

Tšepe Kereiti re tloaetse ho sebelisa. (Ho ka ba joalo ka litlhoko tsa hau.)

Lik'hemik'hale% ea tšepe ea GX130CrSi29 (1.4777): EN 10295-2002

|

C |

Si |

Mong |

Ke |

P |

S |

Kr |

Mo |

|

1.2 - 1.4 |

1 - 2.5 |

0.5 - 1 |

max 1 |

max 0.035 |

max 0.03 |

27 - 30 |

max 0.5 |

Lik'hemik'hale% tsa tšepe GX40CrNiSi27-4 (1.4823): EN 10295-2002

|

C |

Si |

Mong |

Ke |

P |

S |

Kr |

Mo |

|

0.3 - 0.5 |

1 - 2.5 |

max 1.5 |

3 - 6 |

max 0.04 |

max 0.03 |

25 - 28 |

max 0.5 |

K'hemik'hale% ea tšepe GX40CrNiSi25-20 (1.4848): EN 10295-2002

|

C |

Si |

Mong |

Ke |

P |

S |

Kr |

Mo |

|

0.3 - 0.5 |

1 - 2.5 |

max 2 |

19 - 22 |

max 0.04 |

max 0.03 |

24 - 27 |

max 0.5 |

K'hemik'hale% ea tšepe GX40CrNiSi25-12 (1.4837): EN 10295-2002

|

C |

Si |

Mong |

Ke |

P |

S |

Kr |

Mo |

|

0.3 - 0.5 |

1 - 2.5 |

max 2 |

11 - 14 |

max 0.04 |

max 0.03 |

24 - 27 |

max 0.5 |

| Mechini ea mechini (ASTM A297 Kereiti HH) 1.4837 | UTS: Min 75 Ksi / 515 Mpa |

| YS: Min 35 Ksi / 240 Mpa | |

| Ho kopanya: ho 2 ho: Min 10% | |

| Bothata: Min 200 BHN (libaka tse 3 tse sa tloaelehang) " | |

| Microstructure / Metallography | Boholo ba moaho oa Austenitic o nang le li-carbide tse qhalakantsoeng |

| SoundnessTest / X-ray kapa UT | RT ka ASTM E446 Level II |

| UT ka ASTM A609 Level II | |

| NDT / LPI kapa MPI | MPI ho latela ASTM E709 / E125 LEVEL II |

| LPI ho latela ASTM E165 Level II " | |

| Tlhahlobo ea ho qetela ea pono | Lekala la II la ASTM A802 |

| Sephutheloana | Nyeoe ea tšepe kapa nyeoe ea lehong. |

Market rona Main Na

Li-OEM le lik'hamphani tsa boenjiniere

Litšila ho limela tsa Energy

Likhamphani tse sebetsang

Likarolo tsa likokoana-hloko

Litsi tsa motlakase oa mashala

Likhamphani tsa lits'ebeletso bakeng sa ts'ebetso ea tlhokomelo

Mefuta e fapaneng ea mekoallo OEM grate

Libaka tsa grate tse qetileng hantle

Ts'ebetso e holileng tsebong le taolo e thata ea boleng ke hobaneng o tla re khetha

Bakeng sa lipotso tse ling kapa lipotso tsa mahlale, ka kopo ikopanye le Sehlopha sa Ts'ebeletso sa XTJ. Re tla fana ka tharollo e utloahalang ka ho fetisisa ea tekheniki le khotheishene e ntle ho latela sehlahisoa sa hau.